Subsea Hot Tap and

Line Stop

The offshore and subsea environment is part of our DNA at ION PRO Services, with extensive experience working in the offshore subsea environment.

Offshore & Subsea Hot Tap & Line Stopping Capabilities

Our subsea capable equipment successfully performs hot tapping and plugging for pressurized pipeline repair, maintenance, and modification.

Fast Quoting Process

Up to 5,000 psi

Temperatures

up to 200°F

Line Stop Size

up to 48” in diameter

Our Recent Subsea Hot Tap & Line Stop Projects

What to expect during every project?

- Perfect safety record

- Zero pipeline interruption even in extreme environments

- Simplified data sheets

- Easy scheduling

- Fast quoting process

We’re ready to work.

Choose ION PRO Services for Your Next Line Plugging Project

At ION PRO Services, we are committed to respond immediately to avoid piping system disruptions.

Our highly trained team is ready to provide:

- Onshore & offshore line stop solutions

- Line stop machinery

- Welding & fabrication

- Customized line stop manufacturing

- Full compliance

Our line-stopping expertise has been keeping pipelines online safely and efficiently. Rest assured; you are in safe hands with ION PRO.

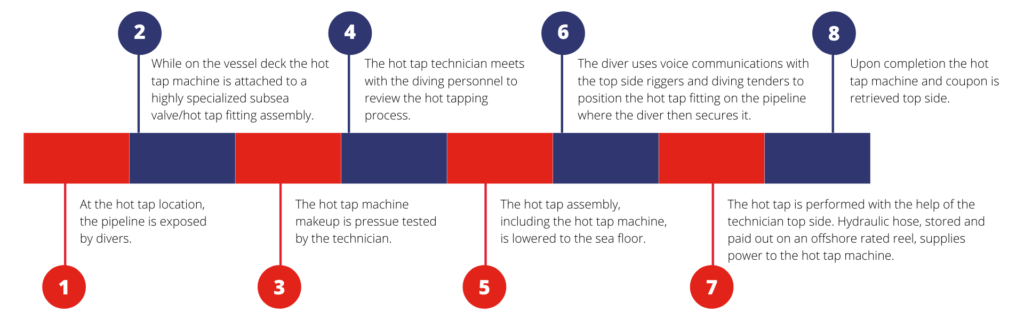

How Are Subsea Hot Tap & Line Stops Performed?

Our subsea hot tap and line stop set up and execution procedures are specialized to work on under-pressure systems up to 5,000 psi.

F.A.Q.

We are responsive to your requests and value your questions. ION PRO Services has proudly served clients seeking turnkey hot tap and line stop services as qualified experts with precision and excellence, with extensive experience in the industry.

Contact Us

Address

21233 FM 529,

Cypress, Texas, USA, 77433-5139

Phone number

Email Address