Engineered Hot Tap & Line Stop Fittings

ION PRO Services provides custom manufacturing of fittings using advance engineering process to minimize or avoid pipeline interruption.

Hot Tap & Line Stop Fittings

Our fittings are designed and manufactured in accordance with ASME B31.3, ASME B31.4 and/or ASME B31.8 and referencing NACE standards and relevant CFR requirements where applicable.

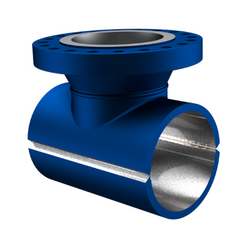

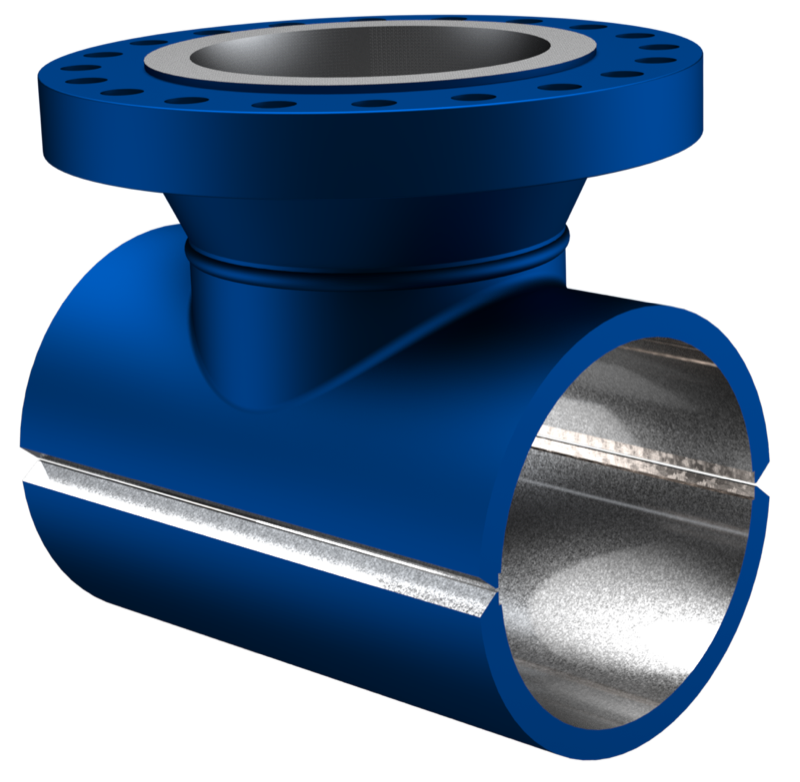

Hot Tap Fittings

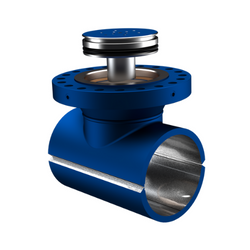

Line Stop Fittings

Line Stop Fitting with Scarfed Nipple

Vent and Equalization Fittings

Flow Through Plug with Pig Guidebars

Double Hub iLOK™ Fittings

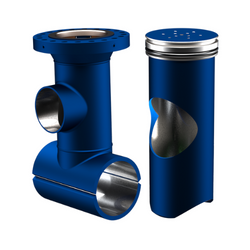

3-Way Tee iLOK™ Fittings

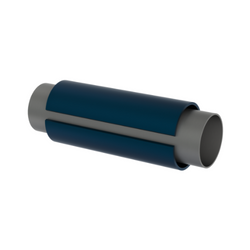

Pipeline Repair Sleeves

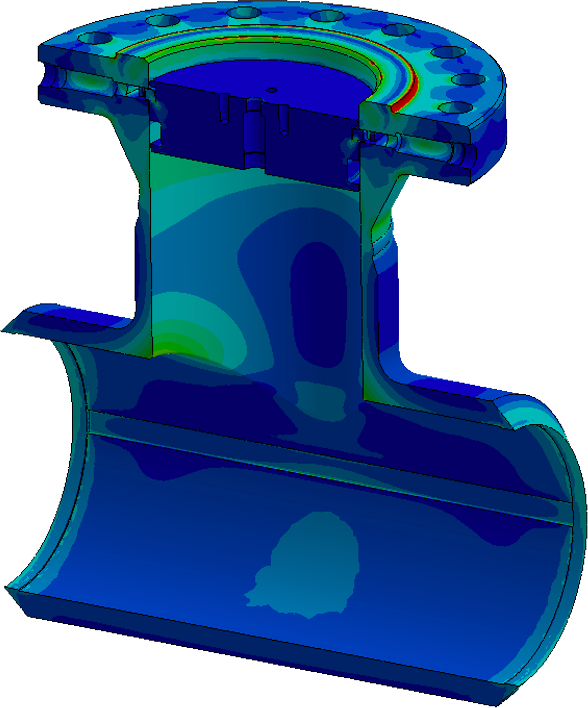

Finite Element Analysis

Supporting the designs of each size range, we conduct a Finite Element Analysis (FEA) on both the iLOK flange and split tee assembly.

ION PRO Services’ hot tap fittings are manufactured using an extrusion or fabrication process, dependent on our customer’s requirements and preference. A case for either method can be made and in reality, both alternatives offer their own advantages, and it comes down to customer and job specific requirements in selecting the preferred option.

Please visit our Insights page to read about a few considerations for both the extruded and fabricated tees.

PROUDLY AMERICAN

Advanced Hot Tap & Line Stop Fittings Engineering

Our fittings are manufactured using either an extrusion or a fabrication process as either of these processes deliver a high quality, engineered fitting that we stake our reputation on.

We understand the high demands placed on the fitting during the intervention process and when we see it is ION PRO, we know it is good to go!

- Designed to ASME B31.3, ASME B31.4 and ASME B31.8 with consideration given to NACE MR 0175 and 49 CFR Subpart D where required.

- Extruded or fabricated – depending on what our customers require

- Size on size or reduced branch.

- Sizes through 42”

- Flanges are rated to ANSI Class 150, 300, 600 and 900

- Material grades ranging from A234 WPB, WPC up to and including WPHY60 with matching flanges.

- Welding conforming to ASME IX and subjected to 100% RT

- Fabrication and manufacturing facilities are certified to ASME U, R, NB and ISO 9001:2015

- Welding backing strips are issued as a standard with all our fittings.

Hot Tap Fittings

Designed to facilitate a branched outlet from an operational pipeline, ION PRO Services’ hot tap fittings are offered in a wide range of sizes with both size-on-size and reduced branch configurations.

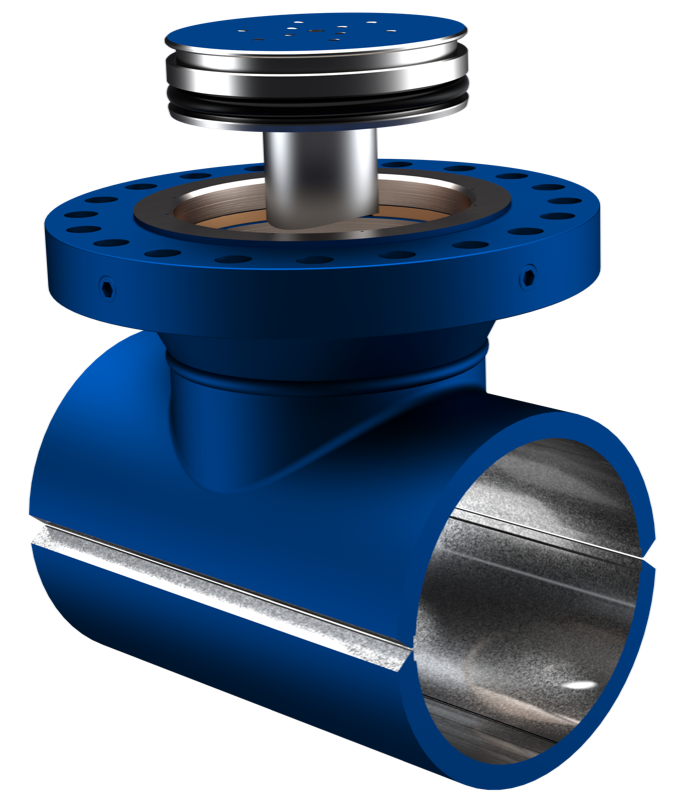

Line Stop Fittings

ION PRO’s iLOK™ Linestop fittings are at the center of any live pipeline intervention. These linestop fitting allow for the connection of hot tap and linestop equipment to facilitate the temporary isolation of a pipeline or pipeline section. The main advantage is that the design of an iLOK linestop fitting allows for the safe removal of all the equipment, including the temporary linestop valve, all while the pipeline remains flowing and under pressure.

The magic lies in the iLOK completion flange and matching completion plug.

What makes an iLOK linestop fitting different from a standard hot tap fitting is the iLOK completion flange. This flange allows for greater flexibility in the use of these fittings and can be used in a variety of ways. The following fittings are great examples of the flexible application of an iLOK completion flange.

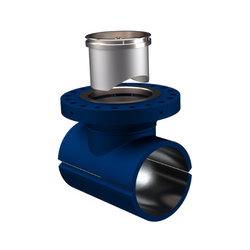

Line Stop Fitting with Scarfed Nipple

This is a hybrid between a standard hot tap fitting and iLOK line stop fitting. The difference being the presence of an iLOK completion flange.

- Non size on size

- Commonly used as a tie in point

- The hot tap service valve remains on the fitting

- A flow through plug with pig guidebars is installed and secured in the iLOK completion flange to ensure the safe passage of pigs of the mainline at the hot tap tie in point.

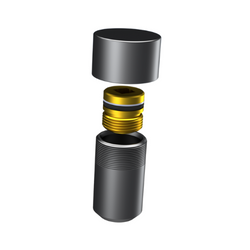

Flow Through Plug with Pig Guidebars

- Works with our standard iLOK completion flange

- Bottom of flow through plug radiused to match the mainline onto which the tie in is being performed

- Allows the flow from the mainline to pass through the tie in valve while maintaining the internal diameter radius to ensure safe pig passage of the mainline at the tie-in point.

Double Hub iLOK™ Fittings

This fitting design is used to minimize the bolted connection of a valve below grade. The one end of the valve is welded to the double hub, while the flanged side of the valve accommodates the hot tap and plug setting equipment.

- The ION PRO Services’ Double hub iLOK fitting facilitates the installation of a flow through plug with pig guidebars the same way a standard iLOK completion flange does.

- The flow through plug with pig guidebars is located and set in the double hub and allows the flow from the mainline to pass through the tie in valve while maintaining the internal diameter radius to ensure safe pig passage of the mainline at the tie-in point.

3-Way Tee iLOK™ Fittings

This is a very versatile fitting because it allows for a below grade tie-in without having a sacrificial valve below grade.

This fitting is equipped with ION PRO Services’ iLOK completion flange, which in turn allows for the setting of a solid iLOK plug with an extended flow through plug and pig guidebars to ensure uninterrupted pigging operations past the hot tap position.

- No sacrificial valve left below grade

- Reduced cost of a tie in

- Reduced lead times

- Solid iLOK completion plug allows for the safe removal of a temporary line stop valve when this tie in is complete.

Extended flow through plug with pig guide bar ensures the safe passage of a pipeline pig in the mainline at the hot tap tie in position.

Vent and Equalization Fittings

The vent and equalization fitting can be used independently or in conjunction with an iLOK line stop fitting when performing a pipeline isolation.

In this function, the vent and equalization fittings are used to bleed down the pressure after setting the line stop plugging heads and again, to equalize the pressure across the line stop plugging heads before these plugging heads are retracted into the line stop housings.

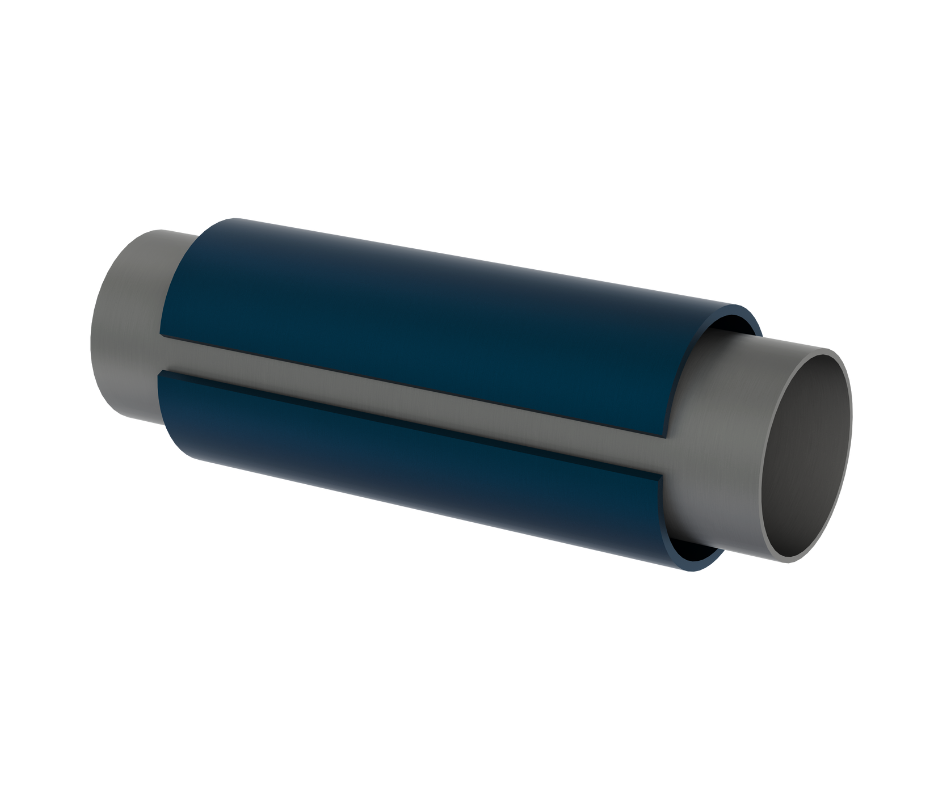

Pipeline Repair Sleeves

Engineered for your pipeline repair needs.

ION PRO’s Pipeline Repair Sleeves are available in a wide range of sizes and grades for lines from 4” to 48” in diameter and grades B, X42, X52, X60, X65 and X70.

Custom lengths available.

Welded Repair Sleeve Features include:

- Restores your pipeline back to its design operating pressure.

- Remediates pipe wall loss due to corrosion or mechanical damage

- Can be installed on an operating pipeline

- Material test reports supplied for each sleeve

- Supplied pre-beveled

Additionally, we offer turnkey pipeline repair sleeves services that include supply and installation of welded repair sleeves using certified in-service welders.

Contact Us

Address

21233 FM 529,

Cypress, Texas, USA, 77433-5139

Phone number

Email Address